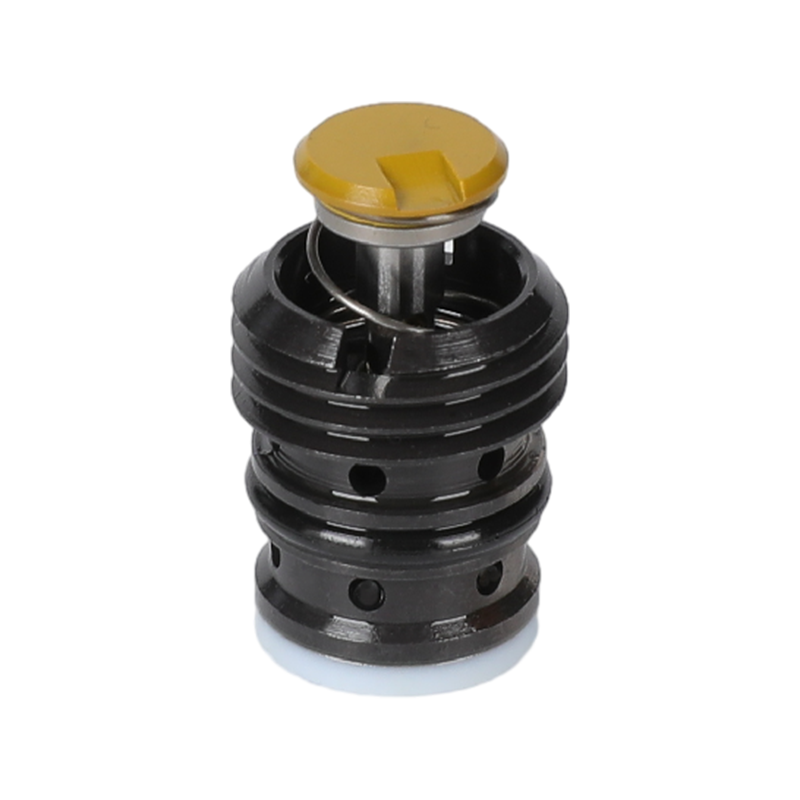

The plug-in valves of this classification are widely used in mobile machinery, and the types and actual uses can be found in specific product information.

ABOUT US

25YEARS OF

EXPERIENCE

News

-

Pressure Control Valve Troubleshooting Tips: Common Problems and Solutions

1. Fault phenomenon: pressure fluctuation or instabilityPossible causes:Valve core stuck or blocked: During long-term use, impurities in the medium (such as dust, corrosi...

READ MORE -

Why Pressure Control Valves Are Essential for System Safety and Efficiency

1. Protect equipment from overpressureOne of the most important functions of a pressure control valve is to prevent the pressure in the system from exceeding the safe ran...

READ MORE -

Check Valves vs. Ball Valves: Key Differences and Applications

1. What is a Check Valve?A Check Valve is a one-way valve designed to allow fluid to flow in only one direction, thus preventing the backflow of the fluid. Its main funct...

READ MORE -

How Flow Control Valves Improve System Efficiency in Hydraulic and Pneumatic Circuits

1. Precise Flow RegulationIn hydraulic systems, flow control valves control the movement speed of actuators (such as hydraulic cylinders or motors) by adjusting the flow ...

READ MORE

Message Feedback

Industry Knowledge Extension

1. What Makes Plug-In Valves the Go-To Choice for Mobile Machinery Applications?

Plug-in valves, also known as cartridge valves or insert valves, offer a unique combination of advantages that make them well-suited for use in mobile hydraulic systems. Their compact size allows for seamless integration into tight spaces, making them ideal for applications where space is limited, such as in construction equipment, agricultural machinery, and material handling vehicles. Additionally, plug-in valves can be easily inserted into manifold blocks or subplates, simplifying installation and reducing assembly time, which is crucial in the fast-paced world of mobile machinery.

Furthermore, plug-in valves are known for their robust construction and durability, capable of withstanding the harsh operating conditions often encountered in mobile applications. Whether it's exposure to shock, vibration, high temperatures, or contaminants, plug-in valves are designed to perform reliably in demanding environments, ensuring uninterrupted operation and minimal downtime. This ruggedness and resilience make plug-in valves the preferred choice for mobile machinery, where reliability and performance are paramount.

Plug-in valves offer versatile functionality, with a wide range of configurations and options available to meet the specific needs of different mobile applications. Whether it's directional control valves, pressure relief valves, flow control valves, or proportional valves, plug-in valves can be tailored to deliver precise control over hydraulic functions, ensuring optimal performance and efficiency in a variety of operating conditions. Plus, their modular design allows for easy customization and adaptation to changing requirements, providing flexibility and scalability for future upgrades or modifications.

Plug-in valves have emerged as the preferred choice for mobile machinery applications due to their compact size, robust construction, versatile functionality, and ease of installation. With their ability to deliver reliable performance in demanding environments and their versatility to meet a wide range of application needs, plug-in valves are the cornerstone of hydraulic systems in mobile machinery.

2. How Do Plug-In Valves Enhance the Performance and Efficiency of Mobile Machinery?

One of the key ways plug-in valves enhance performance is by providing precise control over hydraulic functions, such as direction, flow, and pressure. Whether it's controlling the movement of hydraulic cylinders, regulating the speed of hydraulic motors, or maintaining system pressure within safe limits, plug-in valves offer the accuracy and responsiveness needed to optimize equipment performance and productivity. By fine-tuning hydraulic functions, plug-in valves help mobile machinery operate more efficiently, reducing energy consumption and maximizing output.

Plug-in valves are designed to minimize pressure drops and fluid turbulence within hydraulic systems, optimizing hydraulic efficiency and reducing power loss. This not only improves overall system performance but also extends the lifespan of hydraulic components, reducing maintenance requirements and downtime. Additionally, plug-in valves help ensure system safety by providing reliable pressure relief and overload protection, preventing damage to equipment and minimizing the risk of hydraulic system failures.

Another way plug-in valves enhance the efficiency of mobile machinery is through their modular design and versatility. With a wide range of valve types, sizes, and configurations available, plug-in valves can be tailored to meet the specific needs of different applications, allowing for optimal system design and performance. Whether it's integrating multiple functions into a single valve cartridge or incorporating advanced features like load-sensing or electro-hydraulic control, plug-in valves offer unparalleled flexibility and adaptability for mobile equipment.

Plug-in valves play a vital role in enhancing the performance and efficiency of mobile machinery by providing precise control, minimizing pressure drops, ensuring system safety, and offering versatility in system design. With their compact size, robust construction, and advanced functionality, plug-in valves are indispensable components in hydraulic systems for mobile applications, helping equipment operators achieve maximum productivity and profitability.

3. What Are the Key Considerations When Selecting Plug-In Valves for Mobile Machinery?

One of the first considerations when selecting plug-in valves for mobile machinery is performance requirements. Consider factors such as flow rate, pressure rating, and response time to determine the appropriate valve specifications for your application. Whether it's high-flow directional control valves for heavy-duty equipment or proportional valves for precise speed control in mobile cranes, choosing valves that meet your performance requirements is essential for achieving optimal equipment performance and productivity.

Another crucial consideration is environmental conditions. Mobile machinery often operates in harsh environments, including extreme temperatures, high humidity, and exposure to dust, debris, and other contaminants. When selecting plug-in valves, opt for models that are designed to withstand these conditions, with features such as corrosion-resistant materials, robust seals, and IP-rated housings to ensure reliable operation in challenging environments. Additionally, consider factors such as shock and vibration resistance to minimize the risk of valve failure due to mechanical stresses.

System integration is also an important factor to consider when selecting plug-in valves for mobile machinery. Ensure that the valves you choose are compatible with your existing hydraulic system architecture and can be easily integrated into your equipment design. Look for valves that offer compatibility with standard manifold blocks or subplates, as well as easy-to-use mounting and connection options to simplify installation and maintenance.

Consider factors such as ease of maintenance, availability of spare parts, and support from the valve manufacturer when selecting plug-in valves for mobile machinery. Choose valves from reputable manufacturers with a proven track record of quality and reliability, and ensure that you have access to technical support and assistance when needed.

When selecting plug-in valves for mobile machinery, consider factors such as performance requirements, environmental conditions, system integration, ease of maintenance, and manufacturer support to ensure that you choose valves that meet your specific needs and deliver optimal performance in your application. By carefully evaluating these factors, you can select plug-in valves that enhance the performance, efficiency, and reliability of your mobile equipment, helping you achieve maximum productivity and profitability.

English

English русский

русский

+86-0575-87669088

+86-0575-87669088